Tu dai la priorità

efficienza dei costi e automazioneIl tuo design ha impilamenti di strati simmetrici e tolleranza di allineamento moderataSuggerimento professionale: I moderni sistemi Mass Lam, abbinati a materiali dielettrici avanzati e al controllo della pressa assistito dall'intelligenza artificiale, stanno colmando il divario di precisione. Valutate le capacità del vostro produttore prima di passare al Pin Lam.Nessuno dei due Messa Lam né Lam Pin è universalmente superiore: ognuno eccelle nella sua nicchia. Con il progresso della tecnologia PCB,

L'adozione di massa del Lam è in crescita

nelle applicazioni di fascia media grazie ai miglioramenti nella planarità delle lamiere d'acciaio, nel controllo della pressa e nella scienza dei materiali. Tuttavia,

Pin Lam rimane indispensabile per settori ad altissima precisione.

Per i produttori di PCB, la chiave è allineare la strategia di laminazione con il tuo

roadmap del prodotto, standard di qualità e obiettivi di automazioneCollabora con un produttore che offra entrambe le capacità e le competenze ingegneristiche per consigliare il percorso ottimale.

Ideal for HDI PCBs, high-layer-count boards (>12 layers), rigid-flex, and IC substrates

Requires dedicated pinning and de-pinning stations

Higher operational cost due to pin wear, maintenance, and extra handling

Longer setup time but superior registration control

Best for: Applications where layer-to-layer registration tolerance is critical, such as 5G infrastructure, aerospace, and advanced packaging.

What Is Mass Lam (Pinless Lamination)?

Mass Lam eliminates mechanical pins entirely. Instead, it relies on:

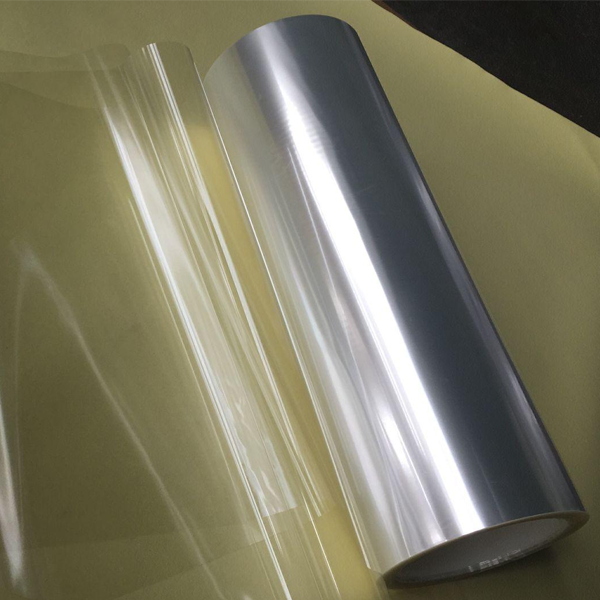

Ultra-flat lamination steel plates (flatness ≤5 μm)

Precision press platen parallelism

Symmetrical inner-layer design

Controlled resin flow dynamics during cure

Key Features of Mass Lam:

Simplified workflow: No drilling or pin insertion/removal

Typical alignment accuracy: ±30–50 μm (advanced systems achieve ±30 μm)

Lower material and labor costs

Higher throughput and better suited for automation

Demands strict control over material symmetry and press uniformity

Best for: High-volume production of standard multilayer PCBs (4–16 layers), such as consumer electronics, networking hardware, and industrial controllers.

Mass Lam vs. Pin Lam: Side-by-Side Comparison

Parameter | Pin Lam | Mass Lam |

|---|---|---|

Registration Accuracy | ±15–25 μm | ±30–50 μm |

Ideal Layer Count | 8+ layers (especially >12) | 4–16 layers |

HDI / Microvia Support | Excellent | Limited (requires evaluation) |

Steel Plate Requirement | Must be drilled; high hole precision | Ultra-flat (≤5 μm), distortion-free |

Press Requirements | Standard | High parallelism, uniform heat/pressure |

Production Throughput | Lower (manual pin handling) | Higher (fully automatable) |

Total Cost | Higher (pins, labor, maintenance) | Lower (leaner process) |

How to Choose Between Mass Lam and Pin Lam?

Selecting the right lamination method depends on your product’s technical and economic profile:

✅ Choose Pin Lam if:

Your design requires tight layer alignment (≤25 μm)

You’re producing HDI, RF, or rigid-flex PCBs

Yield and reliability outweigh cost concerns

✅ Choose Mass Lam if:

You’re manufacturing high-volume standard multilayer boards

You prioritize cost efficiency and automation

Your design has symmetrical layer stackups and moderate alignment tolerance

Pro Tip: Modern Mass Lam systems—paired with advanced dielectric materials and AI-assisted press control—are closing the precision gap. Evaluate your manufacturer’s capabilities before defaulting to Pin Lam.

Neither Mass Lam nor Pin Lam is universally superior—each excels in its niche. As PCB technology advances, Mass Lam adoption is growing in mid-tier applications thanks to improvements in steel plate flatness, press control, and material science. However, Pin Lam remains indispensable for ultra-high-precision sectors.

For PCB fabricators, the key is aligning your lamination strategy with your product roadmap, quality standards, and automation goals. Partner with a manufacturer who offers both capabilities—and the engineering expertise to recommend the optimal path.